Next-Generation Performance: Advanced Coating TechnologiesTransforming Carbide Cutting Tools

Discover how cutting-edge coating technologies are revolutionizing carbide tool performance, extending tool life, and enabling unprecedented machining capabilities across industries.

The Revolution of Advanced Coating Technologies

The carbide cutting tool industry has witnessed a remarkable transformation with the advent of advanced coating technologies. These sophisticated surface treatments have revolutionized tool performance, extending operational life by up to 500% and enabling machining operations that were previously impossible.

"Advanced coating technologies have fundamentally changed the economics of machining operations. What once required frequent tool changes can now run for extended periods with consistent performance."

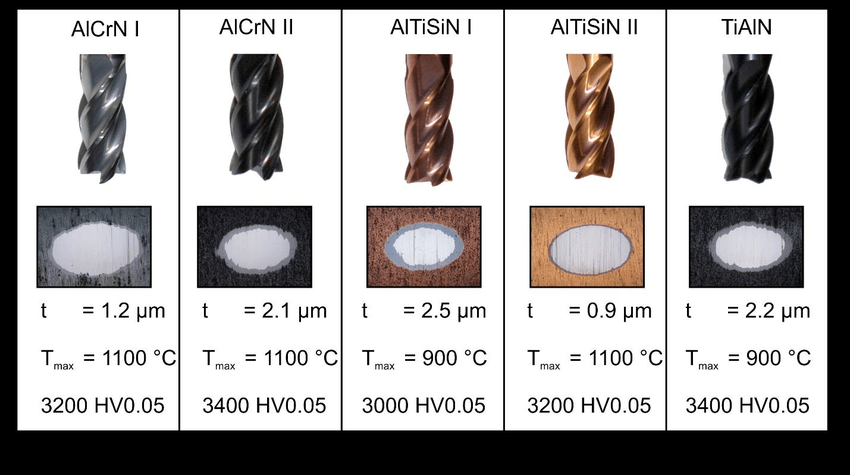

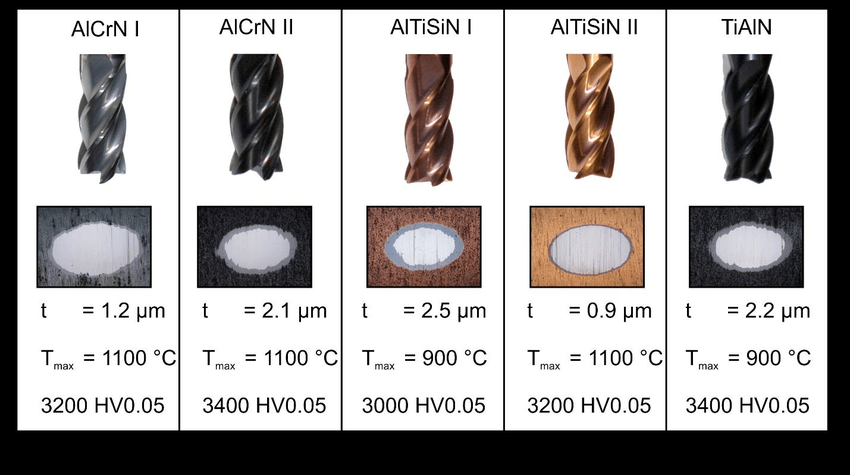

Advanced coating systems applied to carbide end mills showing multiple layer structures

Types of Advanced Carbide Coatings

Traditional Coatings

Titanium Nitride (TiN)

The pioneering coating technology that established the foundation for modern tool coatings.

- Hardness: 2300-2700 HV

- Operating Temperature: 600°C

- Coefficient of Friction: 0.4

Titanium Aluminum Nitride (TiAlN)

Enhanced thermal stability and oxidation resistance for high-speed applications.

- Hardness: 3000-3500 HV

- Operating Temperature: 900°C

- Coefficient of Friction: 0.35

Next-Generation Coatings

Diamond-Like Carbon (DLC)

Ultra-low friction coating ideal for precision machining of non-ferrous materials.

- Hardness: 1000-5000 HV

- Coefficient of Friction: 0.1-0.2

- Chemical Inertness: Excellent

AlCrN-Based Systems

Superior high-temperature performance and excellent oxidation resistance.

- Hardness: 3200-3800 HV

- Operating Temperature: 1100°C

- Thermal Stability: Outstanding

PVD vs CVD: Process Comparison and Selection

Physical Vapor Deposition (PVD)

PVD processes operate at relatively low temperatures (200-500°C), making them ideal for maintaining substrate properties while achieving exceptional coating adhesion.

Key Advantages:

- Excellent edge retention due to low processing temperature

- Superior coating adhesion with minimal thermal stress

- Dense, non-porous coating structure

- Environmental friendly with minimal waste

Chemical Vapor Deposition (CVD)

CVD processes operate at higher temperatures (900-1050°C), enabling the formation of extremely hard, wear-resistant coatings with excellent thermal stability.

Key Advantages:

- Exceptional hardness and wear resistance

- Superior thermal stability at high temperatures

- Excellent chemical inertness

- Uniform coating thickness on complex geometries

Carbide insert showcasing advanced multi-layer coating technology

Multi-Layer Coating Systems: Architecture and Benefits

Modern multi-layer coating systems represent the pinnacle of surface engineering technology. These sophisticated architectures combine different materials in precisely controlled layers to optimize specific performance characteristics for demanding applications.

Adhesion Layer

Typically titanium or chromium, ensures strong substrate bonding

Diffusion Barrier

Prevents interdiffusion between substrate and functional layers

Functional Layers

Multiple alternating layers for optimized wear resistance and hardness

Advanced coating systems applied to carbide end mills showing multiple layer structures

Performance Improvements and Measurable Benefits

Conclusion: The Future of Advanced Coating Technologies

Advanced coating technologies represent a fundamental shift in carbide cutting tool performance. From traditional TiN coatings to today's sophisticated multi-layer systems, the evolution continues to push the boundaries of what's achievable in precision manufacturing.

Key Takeaways

- Advanced coatings can extend tool life by 300-500%

- Multi-layer systems offer superior performance over single-layer coatings

- Proper coating selection is critical for specific applications

- ROI typically exceeds 250% within the first year